Production process

Working from the raw material to the finished product, going through all the consulting and design of the components

PMP MULTITASK shares with its customers all the required steps for the realization of the piece, analyzing the history of operations and proposing suggestions for improvement

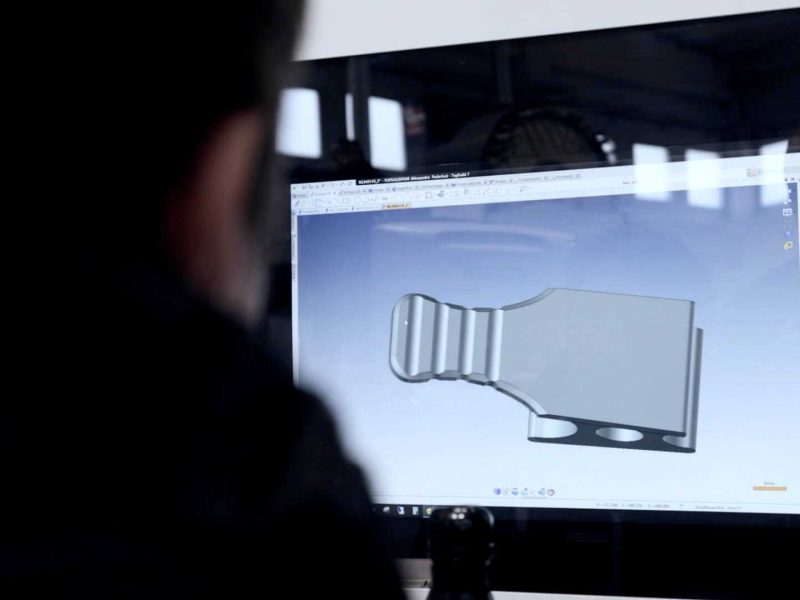

Component development consulting (DFM)

Our team of engineers at PMP has over 30 years of experience helping customers find the perfect manufacturing approach for their components.

Our experts will guide you through the Design for Manufacturing process, ensuring maximum efficiency and cost-effectiveness and identifying the best compromise between design, ergonomics and performance.

Time to market

Meeting lead times is essential for our partners in new product launches and inventory management. PMP offers logistics solutions such as "VMI".

Done in one

With our machining centres, the finished product is obtained in a single machine placement, reducing lead time and increasing precision thanks to the integration of all the necessary operations.

Stress free machining

Our technical approach avoids overheating and stress of the component, especially in PH materials. This minimizes dimensional variations and geometric deformations.

Certifications

Since 2014 we have been certified ISO 13485:2016, an internationally recognized standard.

Our workings

CNC machining

Tumbling

Electropolishing

Mechanical polishing

Washing and decontamination

Laser marking

Laser welding

Shot peening

Injection moulding

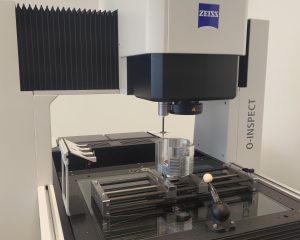

Quality check

Contacts

Useful links

© 2026 PMP MULTITASK S.R.L.

·

VAT Number 03457330235

·

Share capital € 35.000 i.v.

·

REA MN-265251

·

PEC pmpmultitask@legalmail.it